In the realm of industrial and plumbing applications, the demand for materials that can withstand the rigors of high temperatures and pressures is paramount. This is where brass ball valves shine, offering a combination of durability, corrosion resistance, and performance that makes them an ideal choice for various systems.

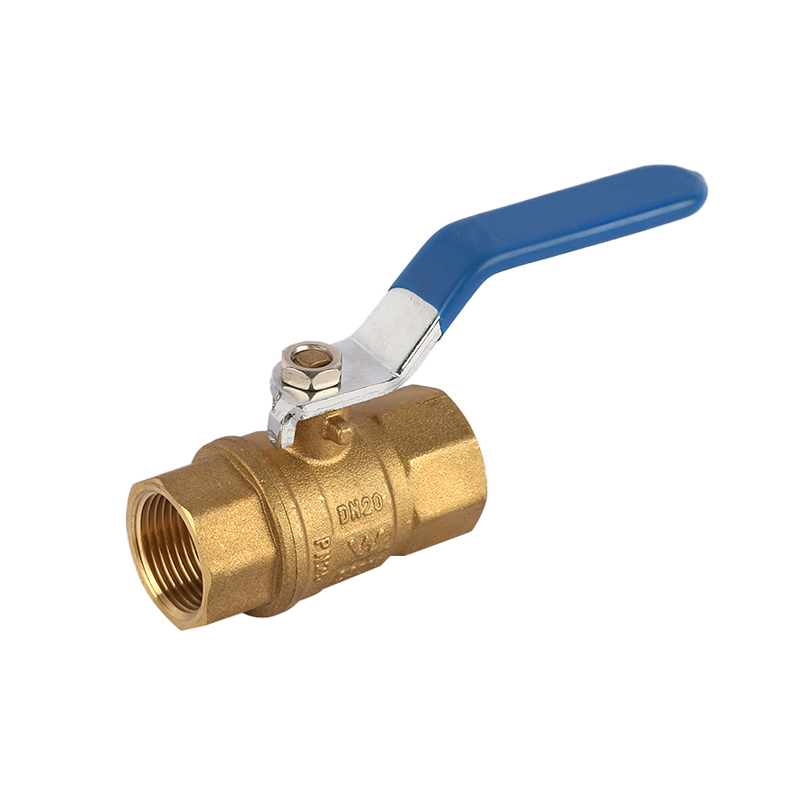

Brass ball valves are known for their exceptional ability to manage thermal stress without compromising structural integrity. The material's unique properties allow it to maintain its shape and function even in the face of heat, making brass ball valves a popular selection for heating systems. Their design, which incorporates a spherical disc that rotates within a cylindrical bore to control flow, ensures a smooth and efficient operation that is not only reliable but also long-lasting.

The construction of brass ball valves is a testament to the material's versatility. Brass, a copper-zinc alloy, is renowned for its ability to resist corrosion and maintain its integrity in harsh environments. This characteristic is particularly beneficial in hot water pipelines, where the combination of high temperature and water can be a recipe for corrosion in lesser materials. Brass ball valves, however, thrive in such conditions, providing a seamless flow of water without the risk of leakage or failure.

One of the key advantages of brass ball valves is their ability to handle high pressures. In industries such as oil and gas, where pressures can reach high levels, the robustness of brass ball valves is indispensable. Their tight seals and sturdy construction ensure that they can manage the pressure without risk of rupture or deformation. This makes them a preferred choice for applications where safety and reliability are important.

The threading and sealing mechanisms of brass ball valves are also worth noting. The threads are precision-engineered to provide a secure fit, which is crucial in maintaining the integrity of the system. The sealing, often achieved through the use of high-quality gaskets or by the inherent sealing properties of the brass itself, ensures that there are no leaks, even under varying conditions of temperature and pressure.

Maintenance is another area where brass ball valves excel. Their resistance to corrosion means that they require less frequent servicing and can operate for extended periods without the need for replacement. This not only reduces downtime but also lowers the overall cost of ownership, making them an economical choice for long-term projects.

In terms of design, brass ball valves offer a wide range of options. They can be found in various sizes, from small, intricate valves used in intricate plumbing systems to larger, designed models for industrial applications. This adaptability is one of the reasons why brass ball valves are so popular across a broad spectrum of industries.

When it comes to environmental considerations, brass ball valves also have a role to play. Brass is a recyclable material, which means that at the end of its life cycle, a brass ball valve can be repurposed, reducing waste and contributing to a more sustainable future.

In conclusion, brass ball valves are more than just a component in a system; they are a symbol of reliability and performance. Their ability to withstand high temperatures and pressures, coupled with their durability and ease of maintenance, makes them a choice for a variety of applications. Whether it's in heating systems or hot water pipelines, brass ball valves are a testament to the power of material science and engineering. Their presence in the market is a reassurance to engineers and technicians alike that they are choosing a product that will stand the test of time and perform under the demanding conditions.

English

English русский

русский Deutsch

Deutsch